- Home

- Products

- Insulating Material

- Engineering Plastic

-

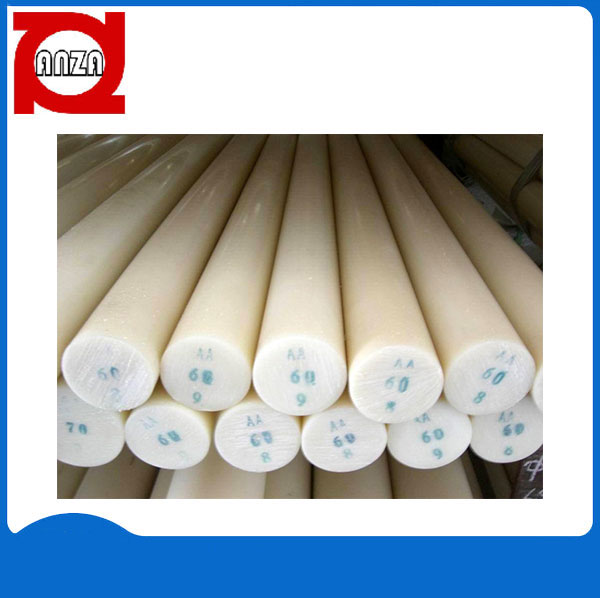

Nylon Rod

Products Application:

Density: 1.15-1.16 g/cm³;

Tensile modulus: 2300 MPa;

Antifreeze: 50 ℃;

Allowable working temperature: 100 ℃;

Electrical strength: 30-35 kV/mm.

The diameter can be from 20mm-300mm -

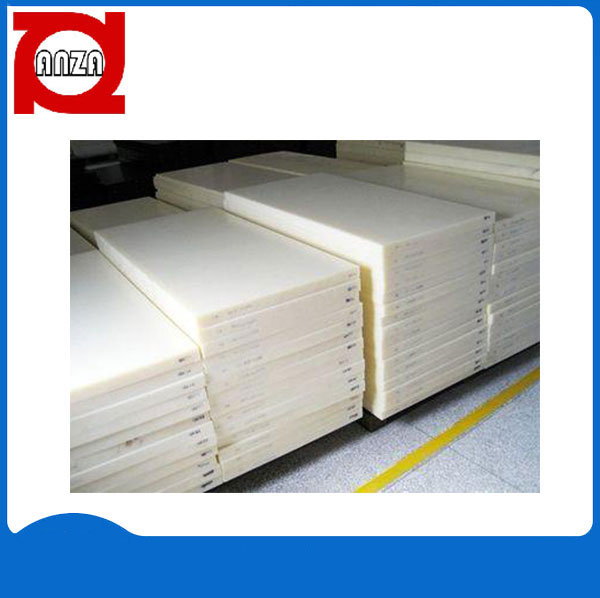

Nylon Sheet

Products Application:

Density: 1.15-1.16 g / cm³;

Tensile modulus: 2300 MPa;

Antifreeze: 50 ℃;

Allowable working temperature: 100 °C;

Electrical strength: 30-35 kV/mm.

The thickness can be from 5mm to 100mm. -

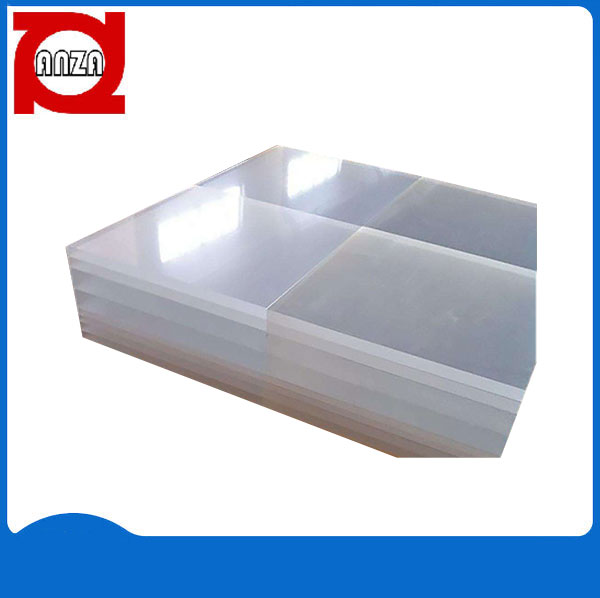

PMMA Plexiglass

Plexiglass plate, without any coloring additives, absolutely transparent, light transmittance up to 92%. Environmental protection and thermoplasticity. The ignition temperature of the material is about 400 °C. Plexiglass has gained the ability to be used in a large temperature range of - 40 to + 90 °C and to improve its strength.

-

Pom Rod

POM rods have high mechanical strength, high rigidity, high hardness, excellent elasticity, sliding and wear resistance, good creep resistance, and even high impact strength at low temperatures, very Good dimensional stability and excellent mechanical properties. It is widely used to manufacture various sliding rotating machines, precision parts, gears, bearings, etc.

-

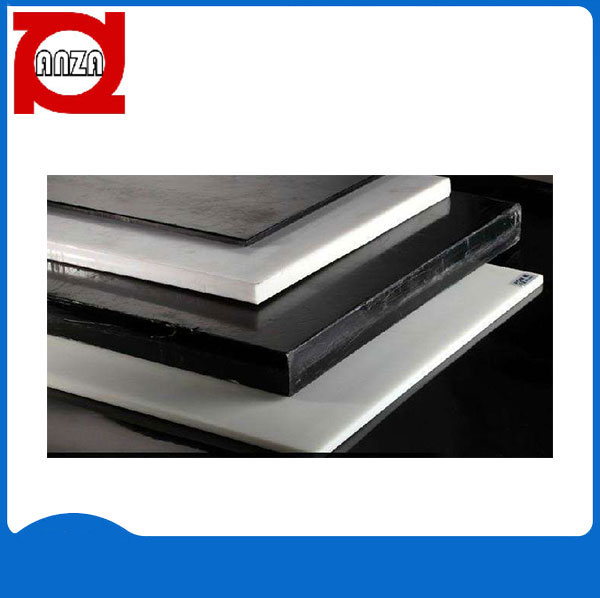

POM Sheet

POM board has high mechanical strength, high rigidity, high hardness, excellent elasticity, sliding and wear resistance, good creep resistance, even at low temperatures, it has high impact strength, very Good dimensional stability and excellent mechanical properties. It is widely used to manufacture various sliding rotating machines, precision parts, gears, bearings, etc.

-

PTFE Air Filtration Membrane

PTFE porous membrane for air filter. The porosity is about 82% and the average pore size is about 0.3um. The film has special functions: high air permeability, excellent chemical stability, low friction resistance, high temperature resistance, etc. After 99.99% lamination. It is the best choice for any kind of high efficiency particulate air filter.

-

PTFE Expanded Tape

The main advantages of tape are heat resistance, enhanced strength, ductility and non-toxicity. It can be used in a temperature range of -60 to + 200 °C. Refers to non-combustible materials with a fire temperature of + 520 °C.

-

PTFE Filament Yarn

Good heat resistance, chemical stability, high tensile strength, low shrinkage, and excellent wear resistance. PTFE fiber is fiber-based and can be processed into various types of high-performance meshes, fabrics, sewing threads, dental floss, membrane structures and other products.

-

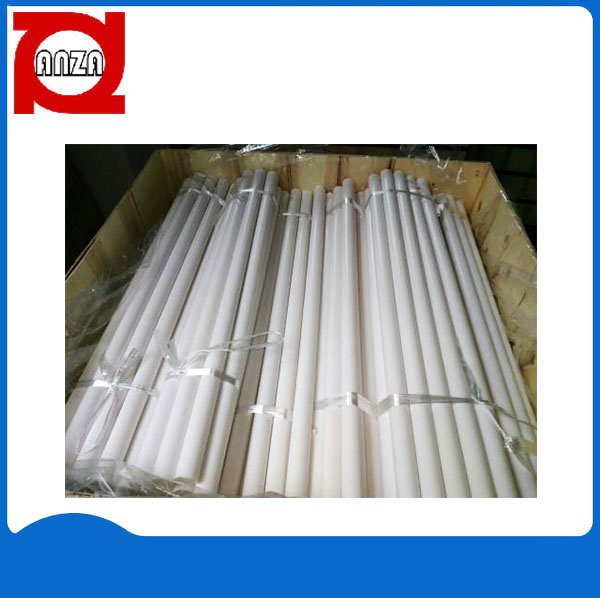

PTFE Rod

Fluorine plastic f-4 rods are widely used as blanks in the manufacture of parts for electrical, friction reduction, sealing and anti-corrosion purposes. The range of f-4 fluoroplastic rods and disks covers mechanical engineering, chemistry, pharmaceuticals, food, nuclear energy, aviation and other industrial fields. The diameter of the rod and the disc can be different: from 6.0 to 330 mm. Depending on the size of the rod, its density may vary. The larger the diameter, the lower the density of the material.

-

PTFE Sheet

The plate-like fluoroplastic sheet has the same quality as the fluoroplastic electrical insulating tube. It is a kind of corrosion-resistant and durable material. In terms of chemical resistance, flaky fluoroplastics are significantly better than special steel, precious metal and enamel. It can be used at - 260 to + 260 degrees for a long time. The melting temperature of the plate is + 327 ℃, and the decomposition temperature is + 415 ℃. The thickness of the plate ranges from 0.8 to 80 mm.

-

PTFE Staple Fiber

PTFE staple fiber with excellent stability, low shrinkage characteristics known, which is widely used in waste incineration power plant dust, cement dust, building materials, steel and other fields.

-

PTFE Tube

Teflon tubes are used for insulated wires. Ftoroplast F4D is a fluoropolymer that is highly resistant to aggressive environments and is an excellent electrical insulation material. It is suitable for long-term operation under the temperature conditions of -196 to +250 degrees.

-

PU Rod

Polyurethane rods have abrasion resistance, chemical resistance, tensile strength, high elasticity, high pressure load resistance, high wear resistance, shock absorption, tear resistance, radiation resistance, high strength, high load bearing and shock absorption.

-

PU Sheet

Polyurethane sheet has abrasion resistance, chemical resistance, tensile strength, high elasticity, high pressure load resistance, high wear resistance, shock absorption, tear resistance, radiation resistance, high strength, high bearing capacity Shock absorption.

-

PVC sheet

The main advantages of vinyl plastic are as follows:

Non-toxic Tasteless.

Flame retardant materials.

Insoluble in ethanol.

It can bond well with concrete, wood and metal.

Withstand temperature conditions from -50 °C to + 60 °C.

Drilling, cutting, grinding, turning and polishing.

Engineering plastics can be used as engineering materials and plastics instead of metal for manufacturing machine parts. Engineering plastics have excellent comprehensive properties, such as high rigidity, small creep, high mechanical strength, good heat resistance, good electrical insulation, which can be used in harsh chemical and physical environment for a long time, and can replace metals as engineering structural materials, but the price is more expensive and the output is smaller.

Engineering Plastic

-

Contact

-

Contact: Rainy (Anshan office)

Tel: +86-412-2972044

Mobile: +86-13384222713

E-mail: myleds@126.com

Contact: Нина Tel: +86-412-8582273 Mobile: +86-412-8582273 E-mail: nina@asanza.com -

Contact: Elena (Dalian office)

Tel: +86-411-39861191

Mobile: +86-13082257788

E-mail: anzaelena@163.com

Contact: Соня Tel: +86-412-8518128 Mobile: +86-15042320637 E-mail: sonia1102@163.com -

Contact: Надя

Tel: +86-412-8582271

Mobile: +86-15541221288

E-mail: asanza2009@163.com

Contact: Аня Tel: +86-412-8582272 Mobile: +86-18841204252 E-mail: liunanlovely@163.com

-

Contact: Rainy (Anshan office)

Tel: +86-412-2972044

Mobile: +86-13384222713

E-mail: myleds@126.com

-

Русский

Русский Español

Español English

English